Means and services

TVAC Chamber

- Principle: Vacuum chamber with integrated thermal regulation. Allows space-grade tests.

- Inner Diameter: 300 mm

- Minimum Temperature: -150°C

- Maximum Temperature: 200°C

- Minimum Pressure: 10^-8 mbar

- Atmosphere: Air / vacuum

- Applications: Aeronautical and space testing

Geometric control

- Principle: Automatic geometric control using profile projection

- Precision: 2 µm

- Capacity: 1 to 100 pieces in automatic mode

Clean room

- Principle: Assembly and testing of components or sub-assemblies in a controlled atmosphere in terms of temperature, pressure and particles

- Class: ISO5

- Area: 30 m²

- MAIT: Manufacturing, Assembling, Integration, Test

Calorimeter

- Principle: Scanning calorimetry measurement

- Minimum temperature: -90°C

- Maximum temperature: 300°C

- Applications: activation temperature of SMAs, glass transition point, etc.

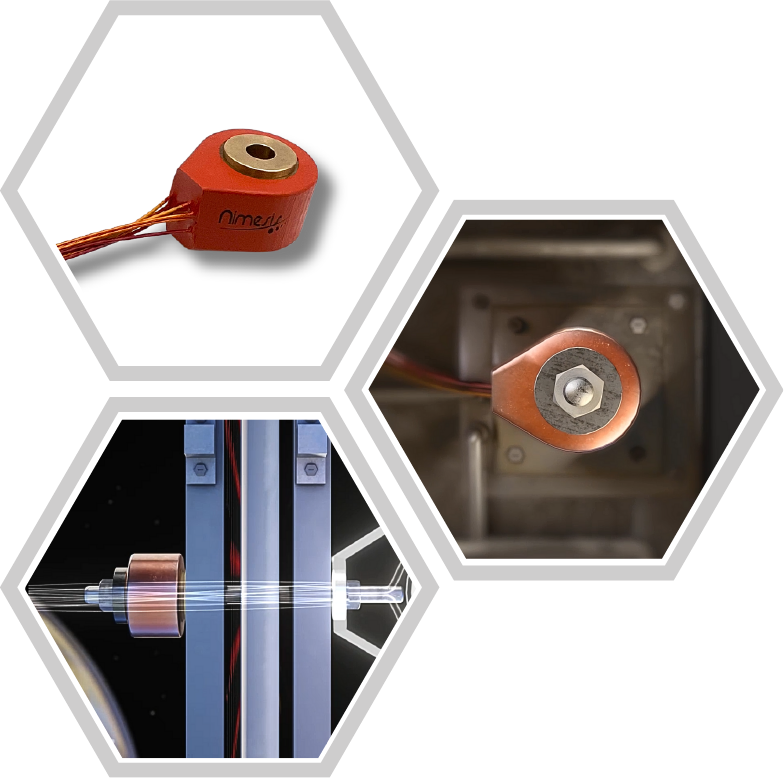

Microwelding Station

- Principle: Micro TIG welding

- Welds under magnification

- Minimum weld diameter: 0.12 mm

- With or without filler material

Mechanical testing machine

- Principle: Traction / compression testing with an integrated climate chamber

- Maxime force: 30 kN

- Temperature-controlled chamber

- Minimum temperature: -70°C

- Maximum temperature: 350°C

Continuous casting furnace

- Principle: Alloy production through continuous casting

- Maximum temperature: 1200°C

- Atmosphere: Air / Vacuum / Argon

- Minimum quantity: 0.2 kg

- Maximum quantity: 2 kg

- Minimum diameter: 2 mm

- Maximum diameter: 34 mm

- Alloys: Melting point <1100°C (Cu, Al based, …)